German Barley, German Malt

The best brewing barley for the best malt

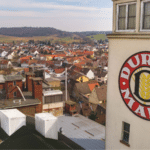

Activity picks up at BESTMALZ’s malthouses in Wallertheim and Kreimbach-Kaulbach at harvest time. Tractors chug as farmers from the region queue up to delivertheir freshly harvested brewing barley. Most have only limited storage capacity and are eager to hand over their crops as quickly as possible. During this period, BESTMALZ extends its operating hours for deliveries; even staying open on weekends, as this is when the basis for all of the company’s products arrive. Not all beer fans are aware that outstanding malt or beer requires excellent brewing barley.

Cultivating brewing barley is not easy

Each year, BESTMALZ processes 90,000 tons of barley and other grains to make its base and specialty malts. It gets the raw materials from different sources, for example, from agricultural and wholesale trade or cooperatives. However, cultivating outstanding brewing barley is by no means straightforward. That’s why for three generations now, the family-owned business from Heidelberg has championed the cultivation of brewing barley and the interests of local farmers. After all, some of the barley used to make malt comes directly from local farmers.

As Michael Huber, Purchasing manager, explains, “At the same time, our suppliers have to meet strict criteria, because brewing barley is complicated to grow. For example, years with little rain produce smaller grains.” Deliveries are screened to ensure that 90 percent of the grains are at least 2.5 millimeters. All barley grains smaller than 2.2 millimeters are rejected and are only sold as animal feed at a considerably lower price.

Brewing barley is a premium product

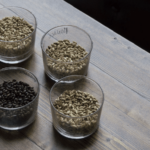

Only specific, specially cultivated types of barley are suitable for brewing. For example, they must produce high yields for the farmer, be resistant to disease, and have sturdy stems. Good malting and brewing properties are also essential to ensure problem-free processing later on. These include protein content, germination potential, and dissolving properties. In Germany, the Malting Barley Association (Braugerstengemeinschaft) identifies and recommends the most suitable varieties of brewing barley every year in its “Berlin Program.”

Varietal purity for higher quality

In Wallertheim, BESTMALZ currently only processes spring barley varieties, while in Kreimbach-Kaulbach, winter barley, as well as wheat and organic grains, are also used. Differences in processing is challenging for storage and logistics, explains Michael Huber, “Both plants malt only one variety at a time, which means keeping different types of grain or varieties of brewing barley separate during intake, storage, and malting. That’s because each variety has different characteristics in the malting process, for example, regarding the amount of water they need for germination or the temperature in the kilning process. Varietal purity is therefore essential for high-quality malt.”

Direct link to producers

BESTMALZ has worked with most farmers in the Palatinate region for many years allowing them to get first-hand information on barley crop quality each year. Shortly before harvest time, the purchasing department and management visit the farms to take stock of the state of the crop to ensure BEST quality.