Winter is right around the corner and we all know what that means! It’s nearly time for new crop malt to be making its way to your brewhouse. Depending on the quality of the previous crop year, this can be a long-awaited moment or a brew where nothing ends up as it was planned! Regardless of if you are dreading or welcoming the new crop, we wanted to share a few tips with you as to how to mitigate the variances from one crop year to the next.

- Check your analysis sheet: Protein increases (or substantial decreases) could cause the need for a protein rest or altered mash in temperatures. An increase in BGs could cause filtration issues or a need for rice hulls. There is a ton of information in your analysis sheets, the more you can understand what you’re working with, and what has changed, the better chance you’ll be set up for success.

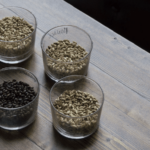

- Check your mill, inspect your rollers, and adjust your mill gap setting: new crop season is the perfect time to give your mill a good look over. Check out the kernel size of your new crop malt versus your old crop malt to be sure that your mill gap is adjusted properly to avoid thru kernels or under milled malt.

- Use your senses. Take a look at the kernels, the coloring. Chew on a few. Do you notice any major variances? Your own sensory analysis is one of the most important pieces to easing the new crop through your brewery. Trust your gut, and ask questions if you have them!

While these tips will help you become acquainted with the new crop year, the best way to be prepared is by knowing your supply chain.

Have you had a chance to talk to your CMG Territory Manager about the new crop? Your territory rep is there for you and has ample information on the crop. Hey, malt is our livelihood, and we’d love to share that info with you! We watch the weather in prime growing regions throughout the year so we know what to expect as the crop progresses. We work alongside our malting companies to be informed on what challenges they are seeing throughout the growing season. And we typically get firsthand information once harvest is complete and the first runs through the malt house have concluded.

This leads to the next pieces of the supply chain. Have you been to a malt house? Understanding the process of making malt can definitely aid you in the brewhouse. Much like brewers in the fall, maltsters are up against taking new crop barley and trying to find the right process to keep the malt as consistent to the previous year as possible, while emphasizing those characteristics that are revealed in the brewhouse, and keeping all other traits in spec. This can be a balancing act, and it usually takes a few batches to narrow into the perfect process for that specific crop year. If you are interested in visiting a Malthouse, just ask! Malthouses can usually accommodate tours when setting up as a guild or association event. Also, some malting companies, like Canada Malting and Briess, are now hosting courses/conferences. Typically held in mid to late summer, these conferences include a tour of a malt house, a visit to a barley field, and numerous sessions packed with technical information that you can take back to your brewery.

The final piece of the puzzle is the farm itself. If you get a chance to visit a barley field or speak with a barley farmer, I recommend it. While maybe not as enthralling as a hop farm, there is something to standing in a field of barley stalks, knowing that these kernels produce a beer that will be in a glass in a few short months. The farmers take pride in the fact that they grow one of the main ingredients in beer and really strive to make sure they are growing what you want to be working within your brewhouse down the line. Their stories are truly the beginning of what we see in that pint glass.