On July 18th, 2012 Governor Andrew Cuomo signed the New York State Farm Brewing Law. The new law allowed for individuals to apply for a Farm Brewery License starting January 1st, 2013. The law was based on the Farm Winery Law enacted in 1976, which spurred an extremely successful wine industry in New York. Under the farm license the licensee can operate up to 5 branch locations, brew/make beer & cider, sell (including by the glass) their own beer & cider including other New York labeled alcoholic products without any additional permits, operate tasting rooms, retail spaces, restaurants, and serve samples and sell at farmers markets. The farm license is also less expensive to acquire and maintain than a regular micro-brewery license.

Since 2013 the state has experienced remarkable growth in the number of breweries. There were 92 breweries operating in New York in 2012, at the end of 2016 there were 320. That currently ranks New York 4th in the country.

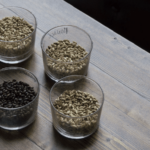

The idea behind the Farm Brewery Law was not just to spur brewery growth but to also spur growth agriculturally, specifically with barley and hops. The breweries are required to use 20%, by weight, New York State ingredients. In 2019 the requirement changes to 60% and in 2024 it changes to 90%. Will the farmers be able to produce both the quality and quantity that the craft brewers demand? The varieties of both barley and hops that can be grown successfully are currently somewhat limited. With the help of Cornell University and Hartwick college among others, there are many experts involved in adapting to the current climate limitations to improve quality and consistency. In addition to the quality of the raw crops, malting the barley and properly processing the harvested hops pose many additional challenges. The barley must be of a specific quality to qualify for malting, then there is the malting process itself. The malting requires specific, expensive equipment and experience to produce a high-quality barley malt for brewing. Hops are extremely vulnerable to oxidation immediately after harvesting and need to be processed promptly and properly to maintain quality. Along with the challenges, the consensus from brewers is that they see improvements year-to-year.

In visiting breweries throughout New York for the past 6 months, I have heard the concerns of brewers on both the current and future state of the available malted barley and hops from New York. There certainly is some high-quality malted barley and hops being grown/produced in New York, and I have heard the praise from

Country Malt Group is trying to meet the needs of New York farm brewers by providing a high-quality, consistent English style 2-row base malt. The New York Empire Malt provides farm brewers just that.

The next few years should prove interesting for NYS farm breweries and raw material producers. The Brewery Farm Law has opened many opportunities in New York State while also producing many challenges. Through the adaptability of all involved, I’m hopeful many will achieve the success this creative law intended. At the same time, producing exceptional beer while supporting your local farmers is simply a win-win.