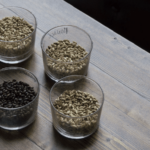

As more Breweries open across the US, it’s important to take a step back and make sure new and even more seasoned brewers understand the basic principles of tank passivation and the differences in the various methods.

When new tanks arrive they are often shipped from the manufacturer without first being passivated.

When new tanks arrive they are often shipped from the manufacturer without first being passivated.

This protective film will prevent microscopic pitting of the stainless steel, which ultimately will lead to a buildup of difficult to clean soils (organic & inorganic). Organic soils deposited on the sides of tanks could lead to infections and dumped beer while inorganic soils such as rust may leach iron, causing oxidative staling of the beer and ruin its shelf life. Passivation also makes general cleaning between brews and fermentations easier as it speeds up CIP times to remove these soils.

Unfortunately, stainless steel is not completely immune to attack from chemicals and requires another layer of protection to fully protect the metal over its useful lifespan.

Sodium chloride in water sources, Peracetic acid sanitizers, organic acids in kettle-sour beer, and even carbon dioxide dissolved in the beer itself all chemically attack stainless steel over time.

The “old school” passivation method (nitric acid in high concentration and then allowed to air dry 24 hrs.) puts down a thin layer of chromium oxide that protects the inside of tanks. This tried and true method works well and is what many brewers use. However, this method does have some drawbacks to newer methods.

The “new” (circa 1990’s) method of passivation deposits a microscopic layer of alkaline cleaner which creates a smooth glass-like surface on the inner walls of the tank whereas the traditional chromium oxide method leaves a rougher surface in the tank which allows soils to adhere more easily. The new method is also faster because you do not need to wait 24 hours to form a protective chromium oxide layer, easier on gaskets and safer overall as you do not need to use as high of temperatures and higher concentrations of chemicals in the process.

“New” tank new passivation method:

- Circulate a hot caustic solution to remove any lubricants and or metal filings leftover from tank manufacture. Rinse well with water to neutralize caustic and drain.

- Perform a visual inspection of the inside of the tank for rust. A high-powered flashlight for looking on the inside of the tank helps. If you have no rust, skip this step. If your tank has rust spots, you will want to circulate 120-130f citric acid solution (a strong Chelator) for 15-30min to clean that off first. Then water rinses to neutralize. If you had rust you will want to immediately move to the next step and not let the tank dry. 2oz. citric acid per gallon of water should work for this. Once this rust is gone, it can come back quickly if not protected by a conversion coating.

- Circulate an acid solution of Nitric & Phosphoric blend (Such as Birko Ultra Niter) for 15-30 minutes 120-130f and NO HOTTER THAN 140F (keep that nitric in the liquid, not in the air).

- DRAIN BUT DO NOT RINSE

- Circulate a non-caustic Alkaline detergent (such as Birko Cell-R-Mastr) to put a phosphate/silicate “conversion coating” on the tank. 15-30 min at 120-130f. 2oz. detergent/gallon water should work.

- Rinse with hot water until pH goes neutral in the tank. Visually inspect. Should be very shiny glass-like. Passivation is now complete however the tank will still need to be sanitized before it can be filled with beer.

This conversion coating process, like the traditional process, is not permanent and should be reapplied a minimum of twice a year. The upside is that it’s easier and faster to do than the traditional chromium oxide method. Country Malt Group carries the needed passivation chemicals in our warehouses from a variety of vendors including Birko, Five-Star, and Shepherd Brothers. Providing the chemical isn’t classified as HAZMAT by the DOT, they can ship along with malt and other products on the same pallet for the standard rate saving money on shipping. If you have further questions about passivation and which chemicals you need, please reach out to your Country Malt Sales Rep.